Empowering Industrial Progress

At KARA Welding & Cutting Industries, we design and manufacture high-performance equipment tailored to the complex needs of oil, gas, refinery, and petrochemical applications. Whether you’re looking for custom-built solutions or technical consultation, we’re here to help.

Petrochemical Tower Manufacturer in Iran

High-Performance Towers for Petrochemical Industry

As a leading Petrochemical Tower Manufacturer in Iran, Kara Sazeh Kimia offers robust, custom-engineered tower solutions designed for critical operations in petrochemical and refinery plants. We provide both standard and tailor-made towers, including distillation columns, absorption towers, and pressure towers.

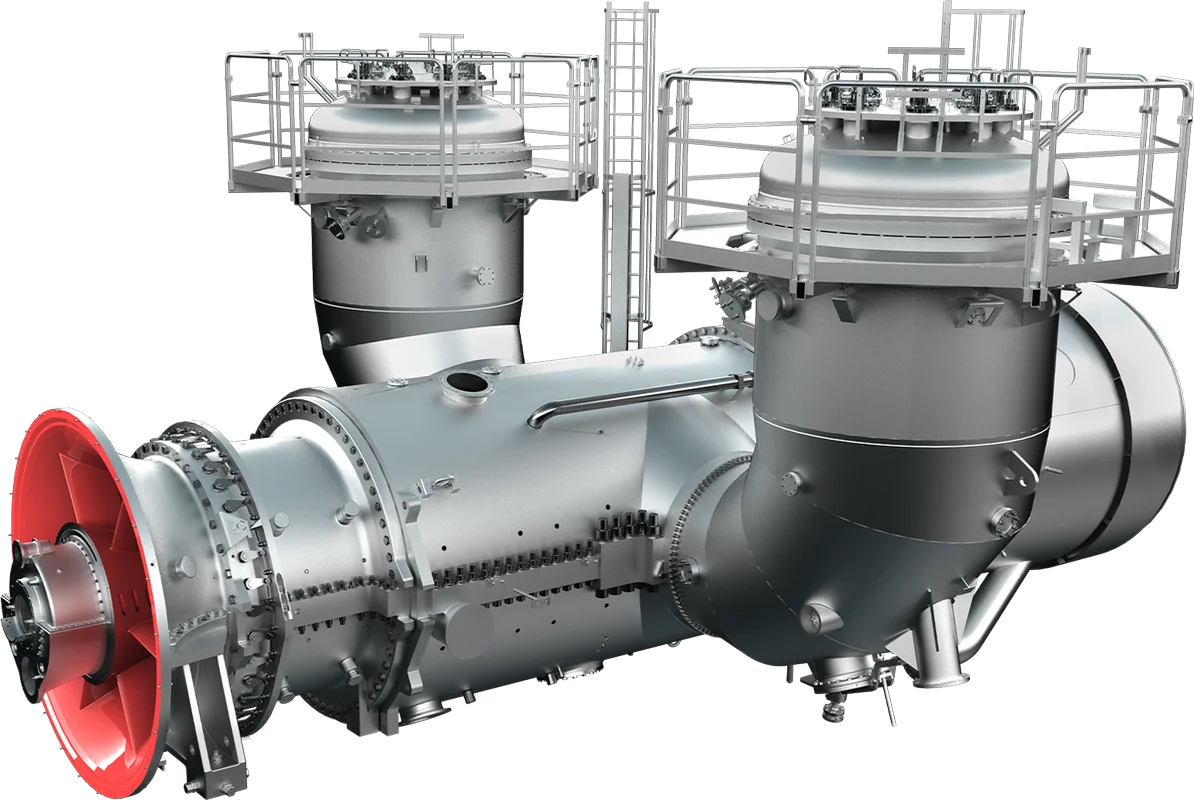

Petrochemical Towers – Precision Engineered for Performance

Kara Sazeh Kimia, a leading Petrochemical Tower Manufacturer in Iran, specializes in the design and fabrication of high-efficiency towers for separation and purification processes in petrochemical, oil, and gas industries.

Product Description

Our petrochemical towers are vertical vessels engineered for precise fractionation and distillation of gases and liquids based on their boiling points. Each tower consists of key components including:

Reboiler: Heats the feed mixture at the base to initiate vaporization.

Column (Tower body): Hosts trays or structured packing materials that enable the rising vapor to interact with the falling liquid for effective separation.

Condenser: Located at the top of the tower, condenses the purified vapor back into liquid form.

Working Principle

The working principle of these towers is based on fractional distillation. The feed enters the reboiler, and the rising vapors pass through the internal structure of the column. Different compounds separate according to their boiling points. Lighter fractions exit from the top, while heavier ones are removed from the bottom.

Advantages

Accurate separation of petrochemical mixtures

Durable and corrosion-resistant materials

Designed for high-temperature and high-pressure operations

Optimized energy consumption and operational safety

As a trusted Petrochemical Tower Manufacturer in Iran, Kara Sazeh Kimia ensures all towers comply with international standards such as ASME, API, and TEMA

Applications

Our towers are used in:

Petrochemical plants

Oil refineries

Gas treatment facilities

Pharmaceutical and chemical processing units

They play a critical role in producing high-purity components such as gasoline, solvents, plastic monomers, and industrial feedstocks.

The working principle of these towers is based on fractional distillation. The feed enters the reboiler, and the rising vapors pass through the internal structure of the column. Different compounds separate according to their boiling points. Lighter fractions exit from the top, while heavier ones are removed from the bottom.

Types of Towers We Manufacture

Distillation Towers Engineered for maximum efficiency and thermal performance in refining and separation processes.

Industries We Serve

- Petrochemical Plants

- Refineries

- Gas Separation Units (GSUs)

- Chemical Processing Facilities

Why Choose Kara Sazeh Kimia?

- ISO-Certified Manufacturing Facilities

- Over 20 Years of Industrial Experience

- Precision Fabrication & Quality Control

- Strong Client Portfolio across Iran & MENA

Internal Links Suggestions

Towers & Columns

Towers are similar to vertical process vessels in that they are erected vertically and they are cylindrical in shape with heads at each end of the cylinder. Towers are, however, normally much taller than vertical process vessels. “Towers” and “columns” are interchangeable name for the same device. These devices have one of two functions. One is to separate a mixture into two or more desired parts. The other function is to transfer a material from one phase to another phase.

- Project name: Pre Depropanizer (T-406)

- Client: Shazand Petrochemical Company

- Run date: 2019-2020

- Main product: Tower

- Weight (ton): 40

- Quantity: 4 set

- Scope of work: Engineering, Procurement & Construction

- Project name: Arak refinery expansion

- Client: Sazeh consultants Co.

- Accomplished Date: 2009

- Main Products: Pressure Vessels

- Weight (ton): 220

- Quantity: 44 set

- Scope of work: Engineering, Procurement & Construction