Oscillator Project: Localization of Advanced Rolling Mill Technology

Kimia Engineering & Industrial Solutions

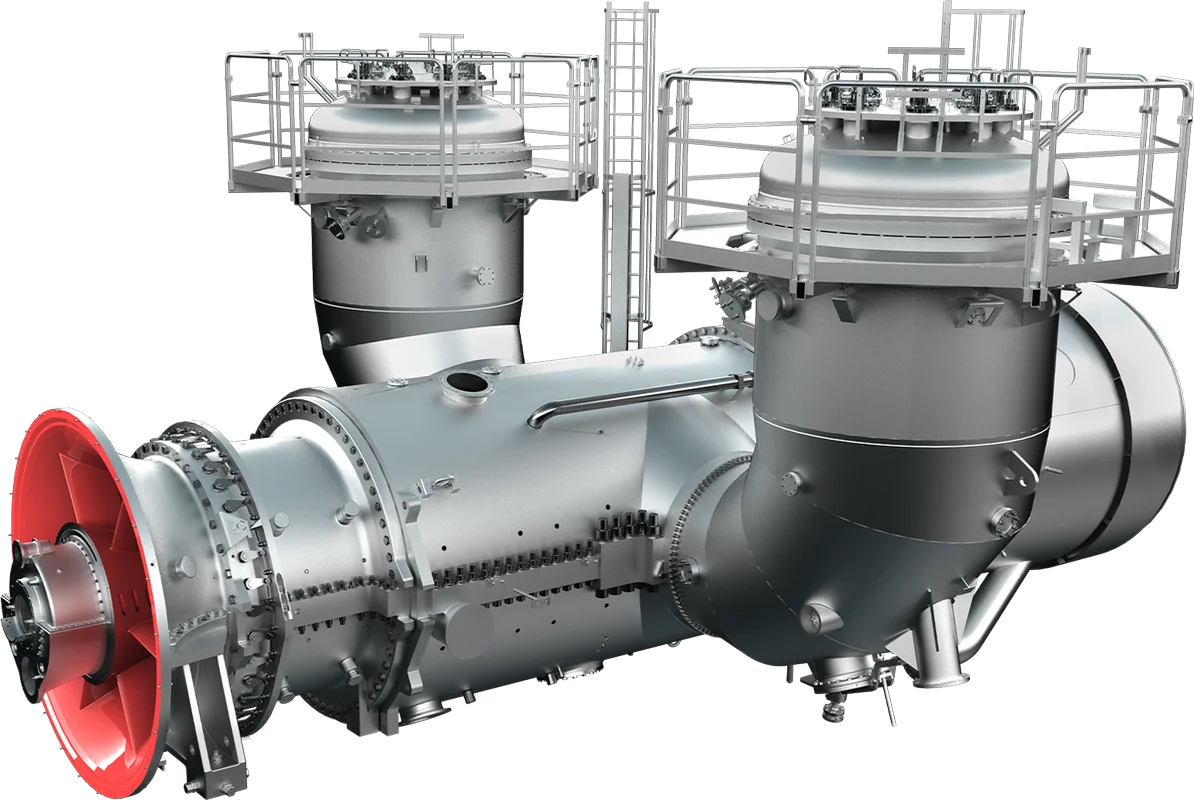

CCM Mold Oscillator

Machine

main products:Machinery

Client :Esfahan’s Mobarakeh Steel Complex (MSC)

Accompished date: 2022

Weight: 72 Ton(36 ton per set)

Qulity: 2 Set

Length:5500mm

height:3500mm

width:3500mm

part: Bodyt Hydraulic Driver & Suspension

Efficient and Innovative Solutions for Oscillator Project

KaraSazeh Kimia’s Oscillator Project for Mobarakeh Steel

The CCM Mold Oscillator Project, delivered to Esfahan’s Mobarakeh Steel Complex (MSC) in 2022, showcases KaraSazeh Kimia’s expertise in precision machinery manufacturing. This project includes two high-performance oscillator units, each weighing 36 tons, with a total weight of 72 tons.

Each unit was meticulously designed and manufactured to include a robust body structure, hydraulic drive system, and suspension mechanism, all built to meet the exacting demands of continuous casting operations. The successful execution of this project marked another step forward in advancing Iran’s domestic capability in the steel production sector.

About the Project

The Oscillator Units of the Continuous Casting Machine (CCM), with a total weight of 72 tons and high-precision mechanical components, reflect KaraSazeh Kimia’s continued commitment to industrial innovation. Delivered to Esfahan’s Mobarakeh Steel Complex (MSC) in 2022, this project involved the manufacturing of two advanced oscillator systems, each including a robust body, hydraulic drive, and suspension unit. A key contribution to the enhancement of casting precision and performance in Iran’s steel industry.

____________________________________________

72 tonnes of precision-engineered CCM Segments delivered to Mobarakeh Steel for advanced continuous casting operations

_____________________________________________

Length:5500mm

height:3500mm

width:3500mm

_____________________________________________

high-precision mold oscillators delivered to Mobarakeh Steel, meeting the highest standards of 2 continuous casting performance.

Oscillator Project: Localization of Mold Oscillator Units for Mobarakeh Steel

KaraSazeh Kimia proudly undertook the localization of Mold Oscillator units for the Continuous Casting Machine (CCM) at Esfahan’s Mobarakeh Steel Complex (MSC), one of the region’s most demanding steel producers.

Completed in 2022, this pioneering project included the fabrication of 2 precision-engineered oscillator units, each weighing 36 tons and measuring 5,500 mm in length, 3,500 mm in width and height. The scope covered body structure, hydraulic drive systems, and suspension mechanisms—all engineered to the highest standards.

This achievement represents a major milestone in Iran’s journey toward industrial self-sufficiency in advanced steel machinery production.

| Title | Descreption |

|---|---|

| Client | Esfahan’s Mobarakeh Steel Complex (MSC) |

| Accompished date | 2022 |

| Weight | 72 Ton(36 ton per set) |

| Qulity | 2 Set |

| Length | 5500mm |

| height | 3500mm |

| width | 3500mm |

Efficient and Innovative Solutions for Segment Project

When KaraSazeh Kimia took on the challenge of localizing the Segment Units (6 to 11) of a continuous casting machine (CCM) for Esfahan’s Mobarakeh Steel Complex (MSC), the aim was clear: to achieve a breakthrough in domestic manufacturing of complex steel industry machinery.

Working closely with MSC, our engineering team designed and produced 16 high-precision segment sets, each weighing 42 tons. These segments included body frames, idler and driver roller packages, as well as integrated hydraulic and cooling systems—components critical to the performance and reliability of the casting process.

By 2024, the project was successfully completed, marking a major milestone in Iran’s industrial self-sufficiency. KaraSazeh Kimia’s accomplishment in this project not only reduced dependency on imported machinery but also proved the company’s capabilities in delivering world-class mechanical systems for the steel production sector.

Bundle Cut: Precision Machinery for Industrial Excellence

he Bundle Cut machine is designed for precision cutting of bundled materials, ensuring clean and efficient separation with minimal waste. Built to meet the highest industrial standards, it enhances productivity and quality in manufacturing processes

Segment :Precision Machinery for Industrial Excellence

Localization of Segment of CCM: Achieving a milestone in Iran’s industrial capabilities, Kara Sazeh Kimia leads the way in localizing the manufacturing of critical machinery segments for enhanced efficiency and self-reliance

Osccilator: Precision Machinery for Industrial Excellence

Oscillators Localization: Kara Sazeh Kimia pioneers the localization of precision oscillator manufacturing, enhancing industrial capabilities and ensuring high-quality, reliable machinery solutions for diverse sectors.