Condenser Manufacturer in Iran

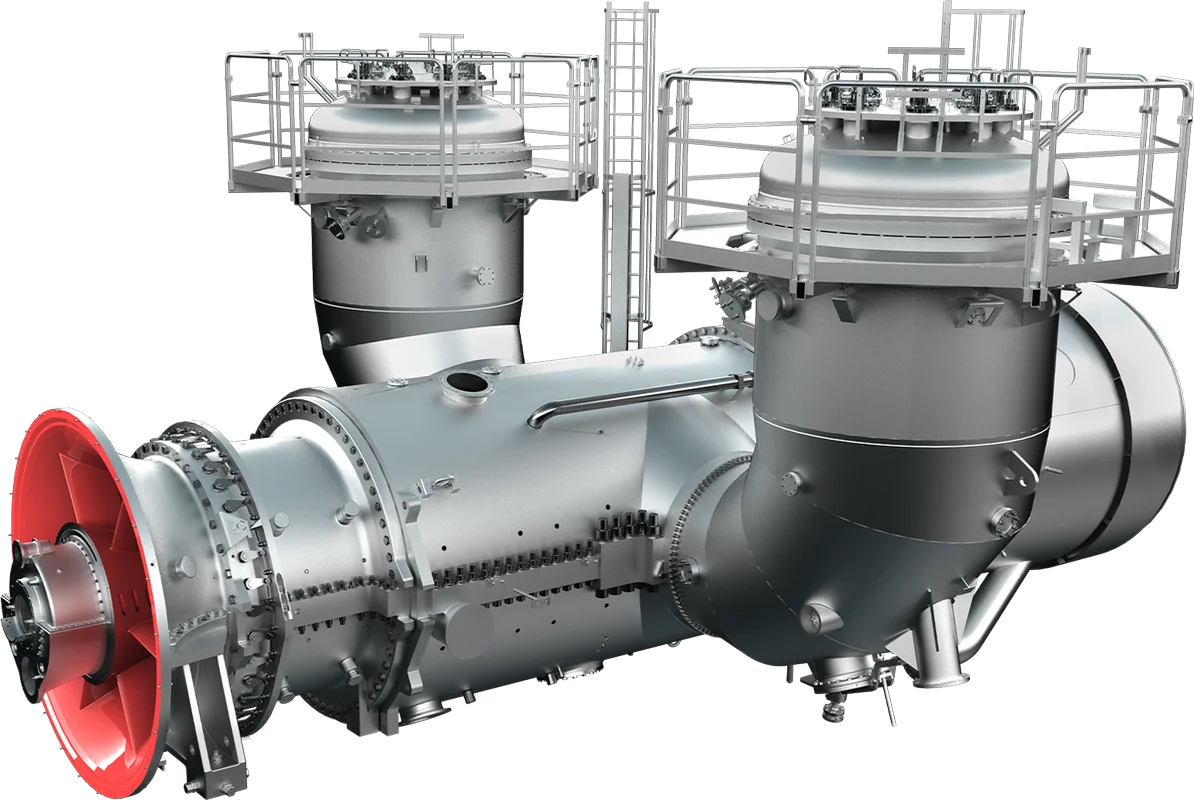

High-Efficiency Condensers for Petrochemical and Industrial Applications

As a trusted Condenser Manufacturer in Iran, Kara Sazeh Kimia delivers high-performance condensers tailored for demanding processes in oil refineries, gas plants, and chemical facilities. Our condensers are designed to optimize heat transfer, improve system efficiency, and ensure operational safety.

Precision Design – Built for Durability and Maximum Heat Exchange

Our condensers are engineered to condense process vapors into liquid by efficiently removing heat using advanced thermal exchange techniques. Whether you need shell and tube, air-cooled, or water-cooled designs, we provide custom and standard solutions based on your application needs.

Product Description

A condenser is a heat exchange device that transforms vapor into liquid by cooling it. Our industrial condensers typically include:

Shell and Tube Assembly: Core structure enabling efficient thermal exchange between hot vapors and cooling fluids.

Tube Bundle: Seamlessly arranged tubes inside the shell that carry the cooling fluid.

Baffles: Direct flow within the shell to increase turbulence and efficiency.

Inlet/Outlet Nozzles: For vapor entry and condensate exit.

Support Structures: For stable installation and maintenance access.

All condensers are designed and manufactured in accordance with ASME, TEMA, and API standards.

Working Principle

Hot vapors enter the condenser and flow over the tube bundle, where a cooling fluid (typically water or air) flows inside the tubes. The heat from the vapor is transferred to the cooling fluid, causing the vapor to condense into liquid, which is then collected and removed from the system.

Key Advantages

condensation of process vapors

High thermal conductivity materials

Corrosion-resistant design for harsh environments

Customizable size, layout, and cooling method

Long operational life with minimal maintenance

Applications

Our condensers are widely used in:

Petrochemical and refinery units

Natural gas processing plants

Power generation and utility stations

Chemical and pharmaceutical production

Waste heat recovery systems

They are essential components in improving process efficiency, reducing energy loss, and enabling product recovery.

Why Choose Kara Sazeh Kimia?

With years of experience as a Condenser Manufacturer in Iran, Kara Sazeh Kimia ensures top-tier engineering, strict quality control, and tailor-made designs for every client. Our equipment is built for reliability, efficiency, and compliance with global industry standards.