Danelli Project: Construction of a Giant Industrial Tank

Kimia Engineering & Industrial Solutions

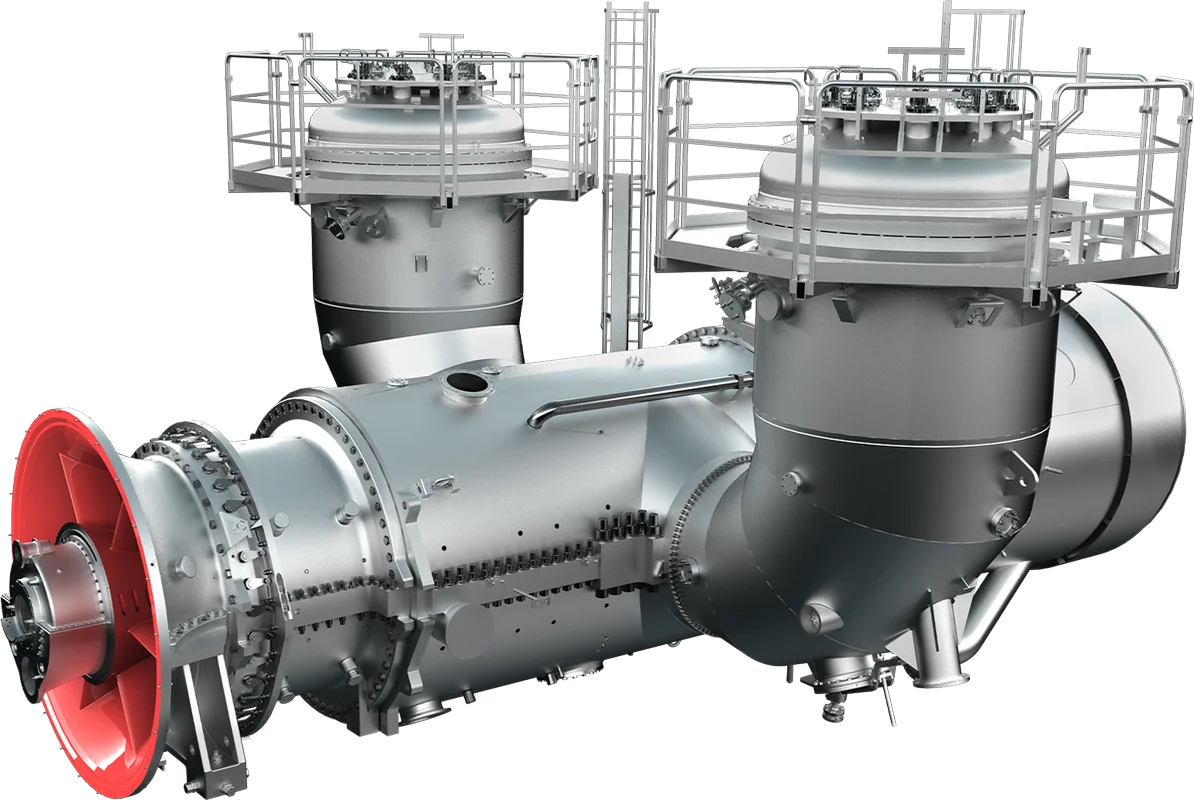

Gas Quench Tower

Pressure Vessels

Client :Danieli Co Butia Iranian Steel making

Accomplished Date:2023

Weight: 650 Ton

Diameter: 7000 mm

Qulity: 19 Set

Lenght:60000 mm

Thickness: 8 to 25 mm

Efficient and Innovative Solutions for Danieli Project

When KaraSazeh Kimia collaborated with Danieli, one of the world’s leading industrial equipment manufacturers, the goal was to develop a cutting-edge production line for heavy-duty steel structures. This project played a crucial role in enhancing automation and efficiency in steel manufacturing.

Working closely with Danieli, our team designed and implemented advanced automation systems to streamline the fabrication process, ensuring precision, reduced waste, and increased production capacity. This partnership led to the successful integration of automated welding, cutting, and material handling technologies into the production line.

By 2024, the Danieli project reached a major milestone, making it one of the most efficient and modernized steel production lines in the region, capable of handling large-scale industrial manufacturing with unmatched precision and speed.

About the Project

The Danelli Gas Quench Tower, with a weight of 650 tons and a diameter of 7,000 mm, stands as a key achievement in industrial tank construction. Designed for Butia Iranian Steel, this 60-meter tower, with thicknesses ranging from 8 to 25 mm, was completed in 2023. A true symbol of innovation and precision in the steelmaking industry

_____________________________________________

650 tonnes of precision-engineered Gas Quench Towers built for Danieli’s advanced steelmaking plant.

_____________________________________________

7,000 mm in diameter, 60 meters in length — engineered for industrial precision.

_____________________________________________

19 high-spec units delivered to meet Danieli’s exacting standards.

Danelli Project: Gas Quench Tower Construction

The Danelli Gas Quench Tower, with a weight of 650 tons and a diameter of 7,000 mm, stands as a key achievement in industrial tank construction. Designed for Butia Iranian Steel, this 60-meter tower, with thicknesses ranging from 8 to 25 mm, was completed in 2023. A true symbol of innovation and precision in the steelmaking industry

| title | descreption |

|---|---|

| Client | Danieli Co Butia Iranian Steel making |

| Accomplished Date | 2023 |

| Weight | 650 Ton |

| Diameter | 7000 mm |

| Qulity | 19 Set |

| Lenght | 60000 mm |

| Thickness | 8 to 25 mm |

The Danelli Gas Quench Tower optimizes steel production efficiency with a robust, custom-engineered design. Combining precision fabrication with high-strength materials, the tower ensures optimal performance in demanding industrial environments. Its advanced structural design, coupled with varying thicknesses ranging from 8 mm to 25 mm, guarantees durability and stability. The tower’s large capacity and scalable dimensions support a wide range of industrial applications, reducing operational costs and improving overall production efficiency

Advantages

- optimized performance in demanding industrial enviroments

- Minimal energy consumption

- Customizable for large-scale applications

- Durable and long-lasting design

- Supports efficient steel production processes

From Concept to Completion

ssfully executed the installation of six high-capacity production units — with a total annual throughput of approximately 30 million tonnes. This complex project involved precision handling and installation of over 650 tonnes of advanced industrial equipment, marking a new benchmark in engineering excellence and international collaboration

“Contact us for project inquiries”

Do you have questions or need more information about our projects? Our team of experts is ready to help!

Whether you’re looking for detailed specifications, custom solutions, or insights into our process, we’re here to provide you with the answers you need. Contact us today to discuss your project requirements, and let us guide you through every step of the way. We’re committed to delivering top-tier, reliable solutions that align with your specific needs.

Related Projects

HC Flare K.O. Drum

iscover the advanced engineering behind the HC Flare K.O. Drum project by Kara Sazeh Kimia. Designed to enhance safety and efficiency in industrial flare systems, our innovative solutions set new standards for reliability and performance.

Gas Quench Tower

Explore the cutting-edge design and engineering of the Gas Quench Tower project. Kara Sazeh Kimia delivers high-performance solutions to optimize industrial processes, ensuring safety, efficiency, and reliability in critical systems

Purge Gas Tank

Uncover the innovative design behind the Purge Gas Tank project by Kara Sazeh Kimia. Our solutions are engineered to enhance safety and efficiency in gas storage systems, meeting the highest industry standards for performance and reliability.