Deaerator , Lp Drum Project: Precision Engineering for Critical pressure vessel

Kimia Engineering & Industrial Solutions

Deaerator , Lp Drum

Main Products:pressure vessel

Client :Mapna Boiler & Equipment Eng. & Manufacturing Co.

Accompished date: 2011

Qulity: 24 Set

Products: Deaerator , LP Drum Feed Water Storage Tank

Weight: 350 Ton

Efficient and Innovative Solutions for Deaerator , Lp Drum Project

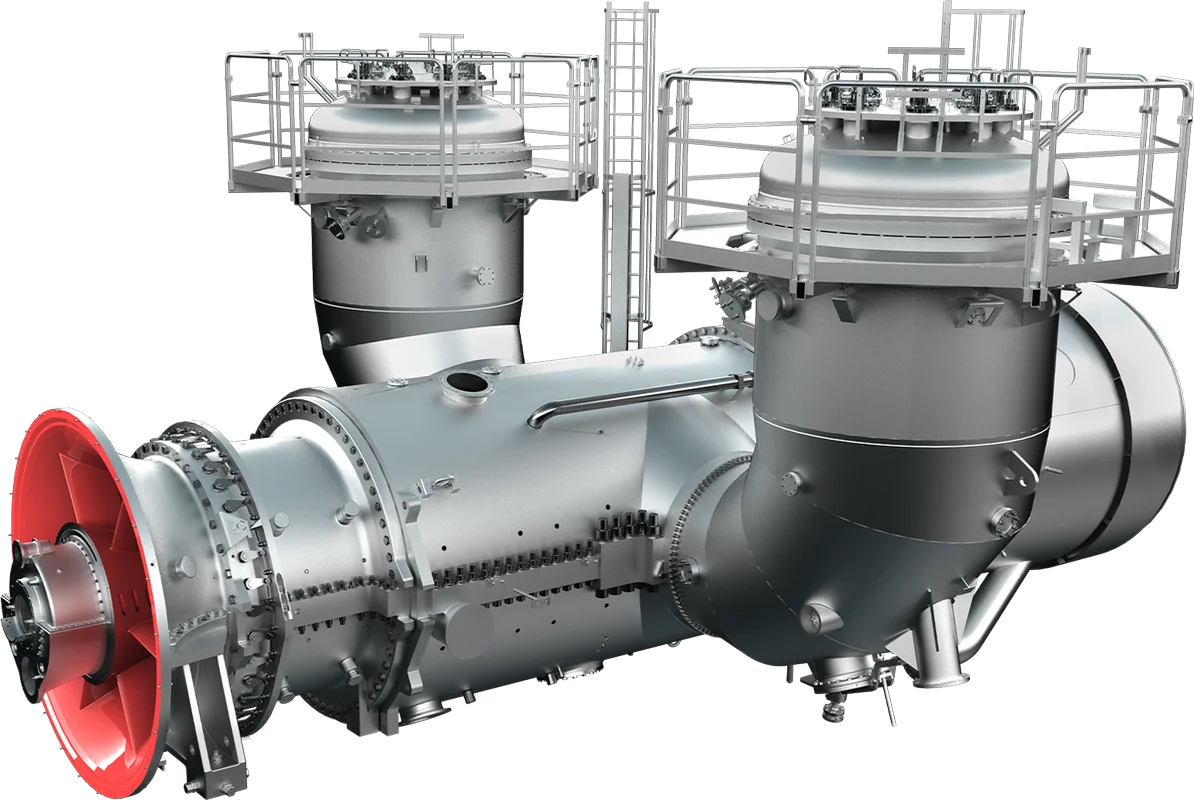

KaraSazeh Kimia’s Deaerator & LP Drum Project, commissioned by MAPNA Boiler & Equipment Engineering and Manufacturing Company, reflects our longstanding expertise in the engineering and fabrication of critical pressure vessels for the power generation sector.

Completed in 2011, this large-scale project involved the production of 24 high-performance units, including Deaerators, Low-Pressure Drums, and Feed Water Storage Tanks, with a combined weight of 350 tons. Designed to operate under the rigorous conditions of thermal power plants, these vessels ensure efficient degassing, condensate recovery, and stable feedwater supply.

Every step—from raw material selection and welding to inspection and delivery—was carried out with strict adherence to international standards, ensuring maximum operational safety, structural integrity, and long service life.

This project stands as a strong example of KaraSazeh Kimia’s capability to support national infrastructure and energy demands with reliable, precision-engineered solutions.

About the Project

The Deaerator & LP Drum Project, comprising 24 custom-engineered pressure vessels with a combined weight of 350 tons, represents a significant achievement in the fabrication of high-performance components for thermal power systems.

Delivered to MAPNA Boiler & Equipment Engineering and Manufacturing Company in 2011, this package included Deaerators, Low-Pressure Drums, and Feed Water Storage Tanks, each designed to operate reliably in high-temperature and high-pressure environments.

This project underscores KaraSazeh Kimia’s technical expertise in producing precision-welded pressure equipment for the power sector—reinforcing the company’s long-standing commitment to quality, operational safety, and engineering excellence.

____________________________________________

350 tonnes of precision-engineered Deaerators and LP Drums delivered to MAPNA Boiler Company for advanced thermal power and feedwater management systems.

_____________________________________________

17,500 mm in length, 35 mm wall thickness — built for high-pressure performance in demanding environments.

_____________________________________________

24 high-performance feedwater vessels, including Deaerators and LP Drums, delivered to MAPNA Boiler Company — setting benchmarks in reliability, efficiency, and thermal power plant integration.

Deaerator & LP Drum Project: High-Efficiency Feedwater Systems for MAPNA Boiler & Equipment Company

The Deaerator & LP Drum Project, completed by KaraSazeh Kimia for MAPNA Boiler & Equipment Engineering and Manufacturing Company in 2011, showcases our long-standing expertise in pressure vessel fabrication. This large-scale undertaking included the production of 24 high-quality units comprising deaerators, LP drums, and feedwater storage tanks, with a total weight of 350 tons.

Designed for efficiency and longevity, these vessels play a critical role in modern boiler and power plant operations—ensuring effective gas removal and reliable feedwater management. This project stands as a testament to KaraSazeh Kimia’s engineering precision and ability to deliver complex equipment for high-performance energy systems.

| Title | Descreption |

|---|---|

| Client | Mapna Boiler & Equipment Eng. & Manufacturing Co. |

| Accompished date | 2011 |

| Qulity | 24 Set |

| Products | Deaerator , LP Drum Feed Water Storage Tank |

| Weight | 350 Ton |

Efficient and Innovative Solutions for Deaerator , Lp Drum Project

KaraSazeh Kimia’s Deaerator & LP Drum Project, commissioned by MAPNA Boiler & Equipment Engineering and Manufacturing Company, reflects our longstanding expertise in the engineering and fabrication of critical pressure vessels for the power generation sector.

Completed in 2011, this large-scale project involved the production of 24 high-performance units, including Deaerators, Low-Pressure Drums, and Feed Water Storage Tanks, with a combined weight of 350 tons. Designed to operate under the rigorous conditions of thermal power plants, these vessels ensure efficient degassing, condensate recovery, and stable feedwater supply.

Every step—from raw material selection and welding to inspection and delivery—was carried out with strict adherence to international standards, ensuring maximum operational safety, structural integrity, and long service life.

This project stands as a strong example of KaraSazeh Kimia’s capability to support national infrastructure and energy demands with reliable, precision-engineered solutions.

Related Projects

HC Flare K.O. Drum

iscover the advanced engineering behind the HC Flare K.O. Drum project by Kara Sazeh Kimia. Designed to enhance safety and efficiency in industrial flare systems, our innovative solutions set new standards for reliability and performance.

Gas Quench Tower

Explore the cutting-edge design and engineering of the Gas Quench Tower project. Kara Sazeh Kimia delivers high-performance solutions to optimize industrial processes, ensuring safety, efficiency, and reliability in critical systems

Purge Gas Tank

Uncover the innovative design behind the Purge Gas Tank project by Kara Sazeh Kimia. Our solutions are engineered to enhance safety and efficiency in gas storage systems, meeting the highest industry standards for performance and reliability.