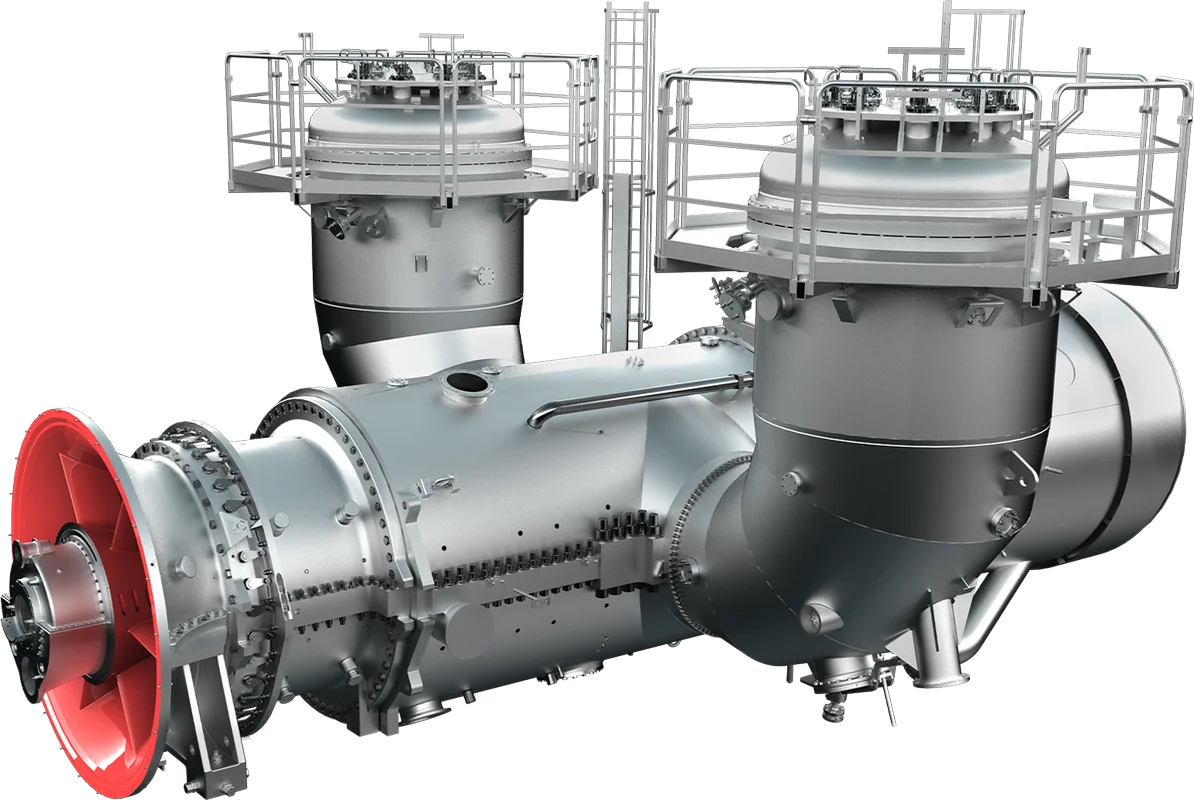

Facilities – Kara Sazeh Kimia

Site & Production Capacity

Kara Sazeh Kimia operates a fully equipped manufacturing complex in Arak, Iran, covering an area of 24,650 m² with an annual fabrication capacity of more than 10,000 tons of industrial equipment. The company employs over 180 skilled personnel, including 34 engineers and project management specialists, ensuring the highest quality in design, fabrication, and execution.

Workshop Equipment

Our workshop is equipped with advanced machinery to handle complex projects:

CNC machines for cutting, cladding, and boring

Plate rolling machines (3- and 4-roll) up to 2,500 mm width and 35 mm thickness

Dish pressing machines up to 100 tons capacity

Heat treatment furnaces up to 1,000 °C

59 welding stations (MMA, SAW, TIG, CO₂)

Sandblasting and industrial painting facilities

Overhead cranes (up to 25 tons) and tank rotators (up to 100 tons)

Quality Control & Testing (QC Equipment)

Before certification, all fabricated equipment undergoes strict quality control, including mechanical, dimensional, and weight inspections. QC facilities are equipped with:

Laser meters, digital level gauges, and theodolites

NDT equipment: UT (analog & digital), MT

Hydrostatic and pneumatic testing facilities

These ensure full compliance with international standards and client requirements.

Engineering & R&D

Our in-house Engineering and R&D department utilizes advanced design tools and experienced professionals to develop innovative, reliable, and efficient solutions. This enables Kara Sazeh Kimia to deliver optimized designs and high-quality equipment tailored to customer needs.

Certifications & Standards

Kara Sazeh Kimia is certified by IMQ with ISO 9001:2008 and strictly adheres to international standards including ASME, API, ISO, DIN, AWS, BS, ANSI, IPS, and EN.

| title | descreption |

|---|---|

| Site & Capacity | 24,650 m² workshop, >10,000 tons annual capacity, 180+ staff, 34 engineers |

| Workshop Equipment | CNC, rolling machines, dish pressing, heat treatment, 59 welding stations |

| QC Equipment | Laser tools, UT, MT, dimensional & weight testing, hydro/pneumatic testing |

| Engineering & R&D | Advanced design tools, innovative solutions, expert engineers |

| Standards & Certifications | ISO 9001:2008, ASME, API, ISO, DIN, AWS, BS, ANSI, IPS, EN |