Purge Gas Tank Project: Precision Engineering for Critical pressure vessel

Kimia Engineering & Industrial Solutions

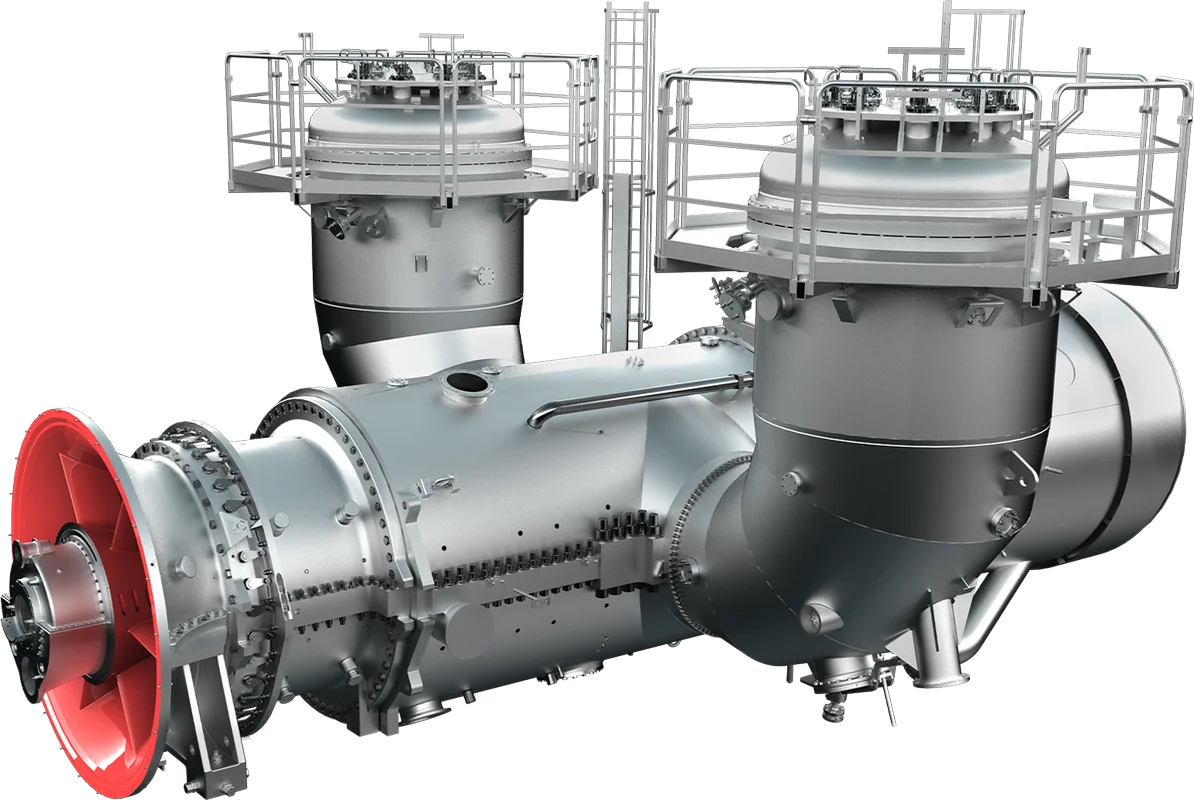

Purge Gas Tank

Pressure Vessels

Client :Fakoor Sanat Tehran Company

Accompished date: 2024

Weight: 480 Ton

Qulity: 6 Set

Diameter: 5000 mm

Length: 17500 mm

thickness: 35 mm

Efficient and Innovative Solutions for Purge Gas Tank Project

KaraSazeh Kimia’s Purge Gas Tank Project, commissioned by Fakoor Sanat Tehran Company, stands as a testament to our deep-rooted expertise in the design and fabrication of high-pressure industrial vessels.

This project, completed in 2024, involved the production of six meticulously engineered pressure tanks, each with a length of 17,500 mm, a wall thickness of 35 mm, and a total weight of 480 tons. These tanks were developed to withstand the demanding operational pressures required in purge gas systems across the oil and gas sector.

From material selection to final assembly, every stage was executed with uncompromising precision, ensuring long-term durability, safety, and compliance with international standards.

These vessels play a critical role in controlling and safely venting excess gases, helping maintain process stability and protect both personnel and equipment in high-risk environments.

The successful delivery of this project reinforces KaraSazeh Kimia’s position as a trusted manufacturer of pressure vessels for some of the most challenging industrial applications, highlighting our ability to meet complex engineering demands with precision and reliability

About the Project

The Purge Gas Tank Project, comprising six high-pressure vessels with a combined weight of 480 tons, marks a key accomplishment in precision fabrication for gas containment applications. Delivered to Fakoor Sanat Tehran Company in 2024, each tank measures 17,500 mm in length with a robust 35 mm wall thickness, ensuring optimal durability under demanding operating conditions. This project highlights KaraSazeh Kimia’s capability in delivering complex welded structures tailored for critical oil and gas processes—reinforcing the company’s commitment to safety, performance, and engineering excellence.

____________________________________________

480 tonnes of high-pressure Purge Gas Tanks delivered to Fakoor Sanat Tehran for critical gas containment in oil & gas operations

_____________________________________________

17,500 mm in length, 35 mm wall thickness — built for high-pressure performance in demanding environments.

_____________________________________________

6 high-pressure vessels delivered to Fakoor Sanat Tehran, exemplifying excellence in industrial tank manufacturing and safety standards.

Purge Gas Tank Project: Precision-Engineered Pressure Vessels for Fakoor Sanat Tehran

The Purge Gas Tank project, delivered by KaraSazeh Kimia for Fakoor Sanat Tehran Company, demonstrates our advanced capabilities in high-pressure vessel production. Weighing a total of 480 tons, this project consists of six precision-engineered sets, each with a diameter of 5000 mm, a length of 17,500 mm, and a thickness of 35 mm. Completed in 2024, these tanks are designed to meet the highest standards of safety and efficiency, ensuring optimal gas management for critical oil and gas operations. This project reflects KaraSazeh Kimia’s commitment to delivering durable, high-quality solutions for complex industrial needs.

If you’d like any adjustments or a more condensed version, just let me know!

| Title | Descreption |

|---|---|

| Client | Fakoor Sanat Tehran |

| Accompished date | 2024 |

| Weight | 480 Ton |

| Qulity | 6 Set |

| Diameter | 5000 mm |

| Length | 17500 mm |

| thickness | 35 mm |

Efficient and Innovative Solutions for Purge Gas Tank Project

KaraSazeh Kimia’s Purge Gas Tank Project, commissioned by Fakoor Sanat Tehran Company, stands as a testament to our deep-rooted expertise in the design and fabrication of high-pressure industrial vessels.

This project, completed in 2024, involved the production of six meticulously engineered pressure tanks, each with a length of 17,500 mm, a wall thickness of 35 mm, and a total weight of 480 tons. These tanks were developed to withstand the demanding operational pressures required in purge gas systems across the oil and gas sector.

From material selection to final assembly, every stage was executed with uncompromising precision, ensuring long-term durability, safety, and compliance with international standards.

These vessels play a critical role in controlling and safely venting excess gases, helping maintain process stability and protect both personnel and equipment in high-risk environments.

The successful delivery of this project reinforces KaraSazeh Kimia’s position as a trusted manufacturer of pressure vessels for some of the most challenging industrial applications, highlighting our ability to meet complex engineering demands with precision and reliability

Related Projects

HC Flare K.O. Drum

iscover the advanced engineering behind the HC Flare K.O. Drum project by Kara Sazeh Kimia. Designed to enhance safety and efficiency in industrial flare systems, our innovative solutions set new standards for reliability and performance.

Gas Quench Tower

Explore the cutting-edge design and engineering of the Gas Quench Tower project. Kara Sazeh Kimia delivers high-performance solutions to optimize industrial processes, ensuring safety, efficiency, and reliability in critical systems

Purge Gas Tank

Uncover the innovative design behind the Purge Gas Tank project by Kara Sazeh Kimia. Our solutions are engineered to enhance safety and efficiency in gas storage systems, meeting the highest industry standards for performance and reliability.