Segment Project: Localization of Advanced Rolling Mill Technology

Kimia,Engineering & Industrial Solutions

Segment of CCM 6 to 11

main products:Machinery

Client :Esfahan’s Mobarakeh Steel Complex (MSC)

Accompished date: 2024

Weight: 672 Ton(42 ton per set)

Qulity: 16 Set

part: Body Frame, Idler & Driver Roler Packages, Hydraulic & Coolding Streams

Efficient and Innovative Solutions for Segment Project

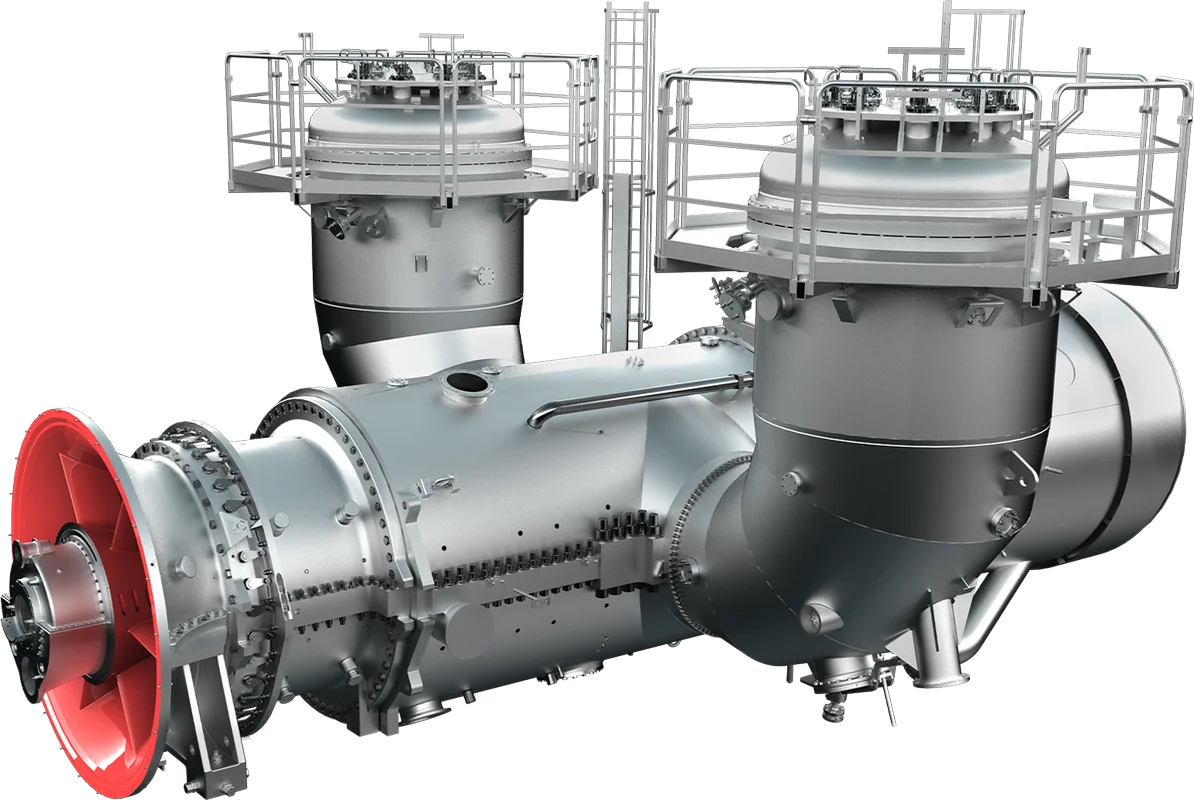

When KaraSazeh Kimia took on the challenge of localizing the Segment Units (6 to 11) of a continuous casting machine (CCM) for Esfahan’s Mobarakeh Steel Complex (MSC), the aim was clear: to achieve a breakthrough in domestic manufacturing of complex steel industry machinery.

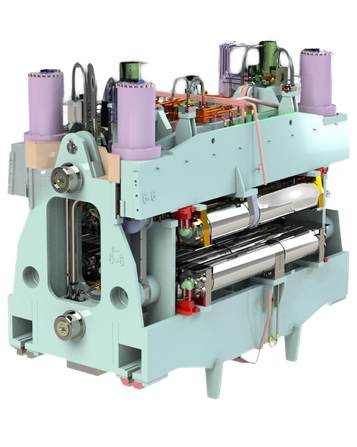

Working closely with MSC, our engineering team designed and produced 16 high-precision segment sets, each weighing 42 tons. These segments included body frames, idler and driver roller packages, as well as integrated hydraulic and cooling systems—components critical to the performance and reliability of the casting process.

By 2024, the project was successfully completed, marking a major milestone in Iran’s industrial self-sufficiency. KaraSazeh Kimia’s accomplishment in this project not only reduced dependency on imported machinery but also proved the company’s capabilities in delivering world-class mechanical systems for the steel production sector.

About the Project

The Segment Units 6 to 11 of the Continuous Casting Machine (CCM), with a total weight of 672 tons and precision-engineered components, represent a significant milestone in localized machinery production. Delivered to Esfahan’s Mobarakeh Steel Complex (MSC) in 2024, this project includes 16 sets of advanced segments featuring body frames, roller systems, and hydraulic & cooling packages. A bold step forward in Iran’s steel manufacturing capability and industrial independence

672 tonnes of precision-engineered CCM Oscillators delivered to Mobarakeh Steel to enhance casting accuracy and efficiency

7,000 mm in diameter, 60 meters in length — engineered for industrial precision.

16 high-precision CCM segments delivered to Mobarakeh Steel, meeting the highest standards of local industrial manufacturing

Segment Project: Localization of CCM Segment Units for Mobarakeh Steel

The CCM Segment Units 6 to 11, totaling 672 tons, mark a major milestone in localized machinery production in Iran. Designed and manufactured by KaraSazeh Kimia for Esfahan’s Mobarakeh Steel Complex (MSC), each of the 16 precision-engineered units includes body frames, idler & driver roller packages, and integrated hydraulic and cooling systems. Completed in 2024, this project highlights the company’s capability in delivering complex steel manufacturing solutions with high standards of accuracy and durability.

| title | descreption |

|---|---|

| Client | Esfahan’s Mobarakeh Steel Complex (MSC) |

| Accompished date | 2024 |

| Weight | 672 Ton(42 ton per set) |

| Qulity | 16 Set |

Efficient and Innovative Solutions for Segment Project

When KaraSazeh Kimia took on the challenge of localizing the Segment Units (6 to 11) of a continuous casting machine (CCM) for Esfahan’s Mobarakeh Steel Complex (MSC), the aim was clear: to achieve a breakthrough in domestic manufacturing of complex steel industry machinery.

Working closely with MSC, our engineering team designed and produced 16 high-precision segment sets, each weighing 42 tons. These segments included body frames, idler and driver roller packages, as well as integrated hydraulic and cooling systems—components critical to the performance and reliability of the casting process.

By 2024, the project was successfully completed, marking a major milestone in Iran’s industrial self-sufficiency. KaraSazeh Kimia’s accomplishment in this project not only reduced dependency on imported machinery but also proved the company’s capabilities in delivering world-class mechanical systems for the steel production sector.

Collaboration and Benchmarking with Leading International and Domestic Casting Machine Manufacturers

As part of its mission to localize high-performance casting machines in Iran, Kara Sazeh Kimia has proudly developed the Segment Project — Iran’s first powerful locally-built segment casting machine. To benchmark this achievement, we highlight a selection of globally recognized companies and platforms in the casting machinery sector.

🌐 Related International Links:

GIFA – The Bright World of Metals

A global trade fair focused on casting technologies and metallurgical innovations.DISA Industries

A world leader in automated metal casting solutions and equipment manufacturing.Italpresse Gauss (Norican Group)

Specialists in high-pressure die casting systems for automotive and industrial applications.Bühler Group – Die Casting Division

A Swiss-based technology leader in die casting solutions for light metal industries.

🇮🇷 Notable Iranian Manufacturer:

Mobarakeh Steel Company

The largest steel producer in Iran, supporting the national metal casting and fabrication ecosystem.

The Products

Bundle Cut: Precision Machinery for Industrial Excellence

he Bundle Cut machine is designed for precision cutting of bundled materials, ensuring clean and efficient separation with minimal waste. Built to meet the highest industrial standards, it enhances productivity and quality in manufacturing processes

Segment :Precision Machinery for Industrial Excellence

Localization of Segment of CCM: Achieving a milestone in Iran’s industrial capabilities, Kara Sazeh Kimia leads the way in localizing the manufacturing of critical machinery segments for enhanced efficiency and self-reliance

Osccilator: Precision Machinery for Industrial Excellence

Oscillators Localization: Kara Sazeh Kimia pioneers the localization of precision oscillator manufacturing, enhancing industrial capabilities and ensuring high-quality, reliable machinery solutions for diverse sectors.